Applied casting technology

What makes aluminum casting unique

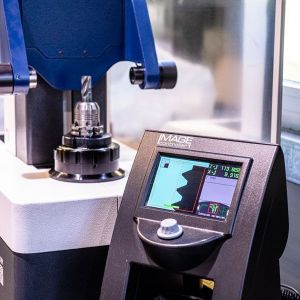

With miguss, you have a reliable and professional partner at your side when it comes to

aluminum casting parts! All products manufactured by us are characterized by impeccable

quality and produced by means of fully automated and ultra-modern equipment. In the

gravity die casting and high pressure die casting process the individually developed and

constructed casting molds are reused: Thanks to this procedure, it is possible for us to offer any scale of production from individual prototypes to large series and to produce even

incredibly complex components in the highest quality.

Gravity die casting

The gravity die casting process is characterized by the fact that during production the molten aluminum is poured into a permanent metallic mold known as a "gravity die". Due to its high thermal conductivity, the permanent mold ensures accelerated cooling of the

solidifying melt. As a result of the rapid solidification, a fine-grained, dense and thus

extremely stable casting is produced. The mold, which is usually made of cast iron or steel,

can be used for further castings after removal of the solidified aluminum product. In this

way, even large series can be easily realized from an economic point of view.

Sand Casting

As the name suggests, the sand casting or sand molding process involves the use of molds

made of sand. This process works on the principle of the lost mold, which means that the

mold is destroyed after being used once to remove the casting. Sand molds are less

expensive to manufacture than reusable metal molds and are particularly suitable for

producing small series or prototypes. Another advantage is that complicated geometries

with undercuts can also be reproduced in the sand casting process - this is not possible, or

only possible to a limited extent, in die casting or permanent mold casting. When using sand casting molds, it is also possible to react more cost-effectively and flexibly to any changes during manufacturing.

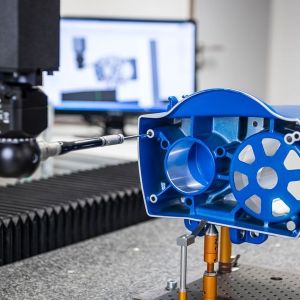

High-Pressure Die-Casting

With high pressure die casting, the liquid aluminum alloy is pressed at high pressure and a very high mold filling speed into a preheated steel mold, in which it solidifies. The molds are

individually developed and designed for each project. The die casting process often allows a drastic reduction in the unit price, which in turn has a positive effect on the overall

production costs.

Scope of application for our high-quality aluminum and magnesium casting

Our scope of application is as diverse and varied as our products. From the optimal casting

design of each individual mold to the packaged end product - with Miguss, you are

guaranteed to receive competent support from our solution-oriented technical staff at all

times. No matter whether it's gravity die casting, high pressure die casting or sand casting: As a reliable partner for high-quality aluminum castings and state-of-the-art CNC manufacturing, we find innovative complete solutions for your industry-specific requirements. In order to be able to offer you first-class work results, we always invest in the latest technology - this is how we set high standards in the production of precision aluminum and magnesium castings throughout the industry.

Our valued customers come from the following industries, among others:

- Aviation

- Marine

- Energy Technology

- Mechanical Engineering

- Construction

- Medicine

- Automotive

Support & Contact

If you have any questions about our services and offers, we are always at your disposal with competent advice. Benefit from our many years of experience and our technical Know-how - do not hesitate to contact us! Our experienced staff will be happy to help you. Click here for direct contact.

"Regardless of whether production of prototypes, small- or mass production of Aluminum and Magnesium casting - at miguss you will find your competent and friendly contact person!"